In the world of vessel operations, efficiency is everything. But in recent years, a new priority has risen to the top of the Chief Engineer’s checklist: Environmental Compliance.

As global shipping continues to face immense pressure to reduce its environmental footprint, the industry is undergoing a massive shift. Central to this shift is AUS40, a fluid that has transformed from a specialty product into a daily operational necessity.

At aus40marine, a division of exhaustfluid.com Inc, we specialize in this transition. But for many operators, questions remain: What makes AUS40 different from standard automotive fluids? And why is it the only viable solution for Tier III compliance?

Here is your comprehensive guide.

What Is AUS40? (It’s Not Just Water)

At first glance, AUS40 appears simple. It is a high-purity diesel exhaust fluid specifically formulated for marine applications. The solution is composed of two primary ingredients:

- 40% High-Purity Urea

- 60% Deionized Water

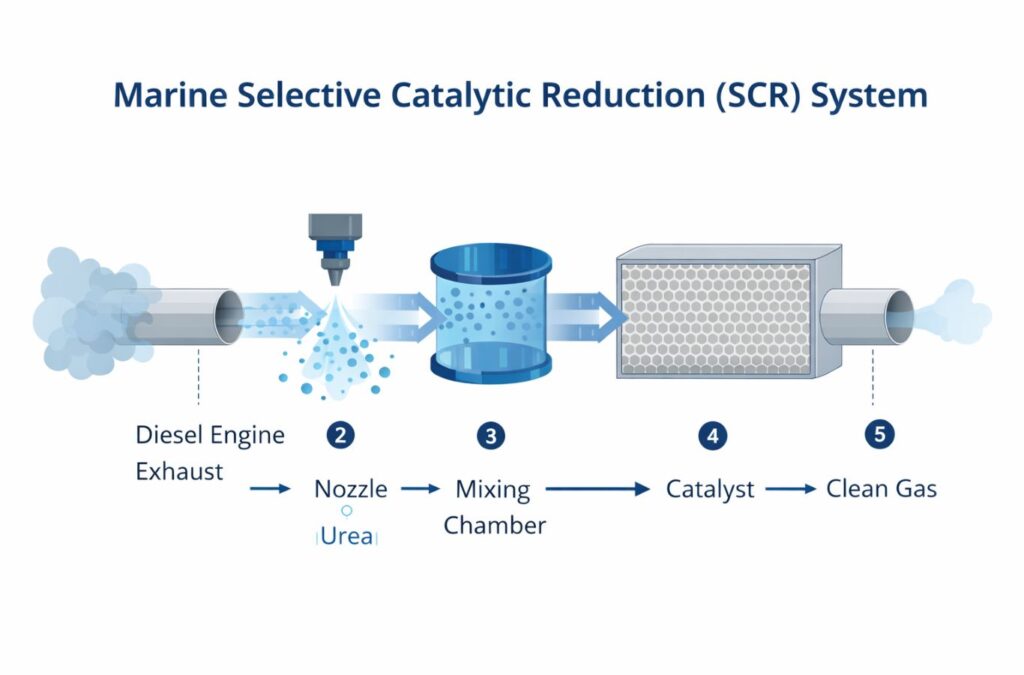

However, this isn’t simply “bulk liquid.” It is a precision-engineered fluid formulated specifically for Selective Catalytic Reduction (SCR) systems installed on ships worldwide.

Unlike lubricants or coolants that keep the engine running, AUS40 is an active chemical agent. When injected into the exhaust stream of an SCR-equipped vessel, it initiates a chemical reaction that breaks down hazardous pollutants before they ever leave the ship’s stack.

The Driving Force: IMO MARPOL Annex VI

The existence of AUS40 is driven by increasingly stringent international maritime regulations.

The International Maritime Organization (IMO) has implemented strict standards under MARPOL Annex VI to curb nitrogen oxide (NOx) emissions. The most significant of these are the Tier III regulations.

Does Your Vessel Require AUS40?

Typically, AUS40 is indispensable for vessels meeting the following criteria:

- Build Date: Ships constructed after 2016.

- Location: Operations within designated Emission Control Areas (ECAs).

- The Goal: A mandatory 80% reduction in NOx emissions compared to previous standards.

This 80% target is aggressive. Engine tuning alone cannot achieve it. This is where AUS40 becomes mission-critical. Without it, modern Tier III vessels simply cannot operate legally in regulated waters.

The Chemistry: Turning Pollution into Vapor

How does a liquid achieve an 80% reduction in pollution? The science is elegant in its simplicity:

- Injection: AUS40 is injected directly into the hot exhaust stream of the vessel.

- Reaction: The heat causes the urea to decompose into ammonia.

- Conversion: This ammonia reacts with the nitrogen oxides (NOx) inside the SCR catalyst.

- Result: The harmful pollutants are broken down into two benign substances: nitrogen gas and water vapor.

This process allows modern vessels to meet strict environmental standards while maintaining operational efficiency.

Why Not Use Automotive AdBlue?

A frequent question from procurement teams is whether they can substitute automotive urea (AdBlue/AUS32). The answer is a definitive no.

While chemically similar, the distinction lies in concentration and engineering:

- AdBlue (AUS32): Designed for automotive applications with lower urea concentration.

- AUS40: Contains a significantly higher concentration of urea (40%).

AUS40 is specifically engineered for the demanding conditions of marine engines. Using a weaker solution like AdBlue in a marine SCR system would result in inefficient NOx conversion and potential non-compliance issues.

The Importance of Purity

Because AUS40 is injected into sensitive SCR hardware, purity is non-negotiable. The fluid must be free of metallic ions and contaminants that could poison the catalyst.

At aus40marine.com, we ensure every drop meets strict quality standards:

- ISO 22241 Compliance: We partner with certified manufacturers who produce to this internationally recognized specification.

- Climate-Controlled Storage: To prevent crystallization or degradation, we maintain optimal temperatures in our facilities.

- Dedicated Equipment: We use stainless steel pumps and hoses exclusively for AUS40 to ensure no cross-contamination occurs.

Conclusion: A Smoother Voyage

The maritime industry’s shift toward AUS40 reflects a broader commitment to environmental stewardship. As vessels adopt SCR systems across global fleets, efficiency at the “final mile” of procurement matters more than ever.

Whether you are a Chief Engineer or a procurement manager, you need a partner who understands that reliable access to clean AUS40 is critical to keeping your vessel compliant and voyage-ready.

Need reliable AUS40 supply? Whether you are at berth or at anchor, we deliver quality you can trust. Contact AUS40Marine Today for a Quote